Project Overview: Wood is a hierarchical material with numerous structural features including growth rings at the millimeter length scale and cells at 10 micron length scale (1/1,000,000 meters). Classical elasticity theory (ex. Metals) is not sufficient to describe the elastic properties of wood when the size of the tested specimens approaches the size of a [...]

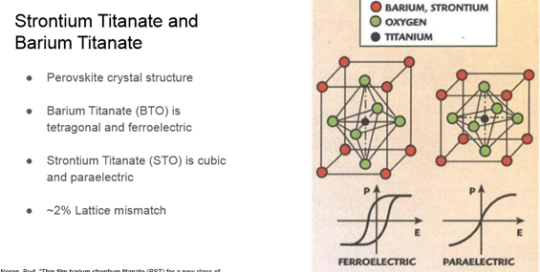

Synthesis of BaTiO3/SrTiO3 multilayer thin films using Solid-phase Epitaxy

rehaas2022-04-13T10:37:46-05:00Project Overview: Heterostructure thin films composed of alternating layers of BaTiO3 (BTO) and SrTiO3 (STO) represent an exciting new direction in materials design for applications in radio-frequency electronics and high-dielectric-constant capacitors. This project will use solid phase epitaxy to crystallize an amorphous BTO/STO multilayer thin film that is deposited on a Si/SiO2 substrate using [...]

Utilization of Machine Learning to Map-Out Features of Potential Perovskite Solar Cell Compositions

rehaas2022-04-13T10:38:07-05:00Project Overview: Perovskites structured compound, most commonly a hybrid organic-inorganic lead or tin halide-based material, are being investigated as an alternative to silicon solar cells. They have unique electronic properties that have the potential to be more efficient than existing solar cells. By altering the composition of a perovskite crystal structure, the properties of the [...]

An Investigation of Isothermal Calorimetry to Measure Corrosion Rates

rehaas2020-05-28T10:24:01-05:00Project Overview: Metal fasteners are being used to hold wood together, however can corrode because of wood preservative treatments. Forest Products Laboratory desires to use a new technique (isothermal calorimetry) to study this corrosion. Isothermal calorimetry methods have not been used before to track the corrosion rates of different metal fasteners in wood samples. The [...]

Mechanical Property Analysis of 3D printed 316L Stainless Steel 3D Parts

rehaas2020-05-28T10:24:45-05:00Project Overview: Powdered metallurgy in Fused Deposition Modelling (FDM) and 3D printing is new technology in the materials science and engineering manufacturing world. The Virtual Foundry is manufacturing small metal parts using a 3D printer with a powder metal filament, and the parts are then sintered (compacted and formed a solid mass of material at [...]

An Examination of Early Stage Oxidation in Nickel Aluminum (Ni-Al) Alloys

rehaas2020-05-28T10:25:04-05:00Project Overview: A significant portion of high temperature materials are Nickel (Ni) based. Long term oxidation in these systems has been thoroughly studied, however often neglecting the microstructure effects (ie. grain boundaries, grain orientation). Additionally, few studies have considered the native oxide growth dependence on orientation as it relates to growth direction. This project will [...]

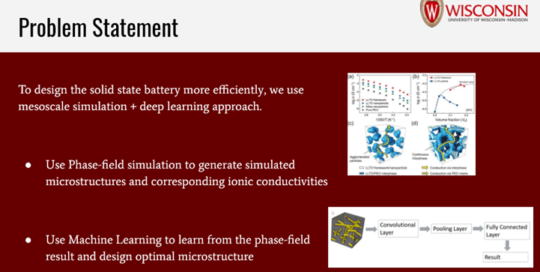

Computer-Aided Microstructure Design of Novel Polymer-Ceramic Composite Solid Electrolytes

rehaas2020-05-28T10:25:44-05:00Project Overview: Batteries currently used today usually consist of flammable liquid electrolytes making it unsafe to users. With this limitation, solid-state batteries then arise to eliminate the limitation, and additionally provide faster charging feature which is a result from higher cation (Li+) mobility. Although significant progress has been made, it is uncertain on how to [...]

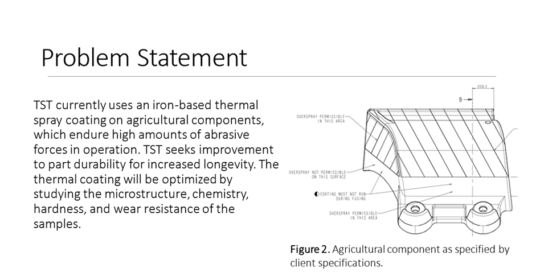

Wear Resistance Improvement of an Iron-Based Thermal Spray Coating

rehaas2020-05-28T10:26:03-05:00Project Overview: Thermal spraying is a technology which improves or restores the surface of a solid material. The process can be used to apply coatings to a wide range of materials and components, to provide resistance to: wear, erosion, cavitation, corrosion, abrasion or heat. Thermal Spray Technologies (TST) is looking for improvement to their current iron-based thermal spray [...]

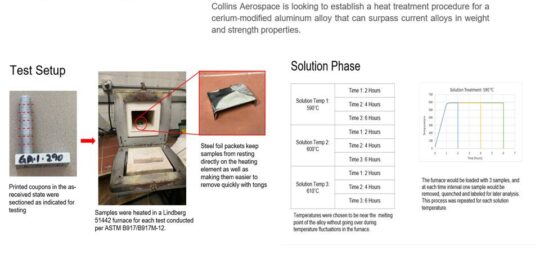

An Investigation of a new Aluminum Alloy for Additive Manufacturing

rehaas2020-05-28T10:26:27-05:00Project Overview: The aerospace industry is exploring the use of additive materials (Metal Matrix Composites) in the aircraft manufacturing process. Collins Aerospace has a new nickel-based super Aluminum Alloy that possesses high strength properties and resistance to elevated temperatures. During additive manufacturing (powder metallurgy) one step is Sintering. Sintering is the process of compacting and [...]

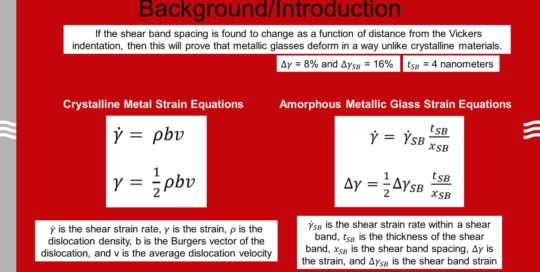

Investigation of Shear Bands in Bulk Metallic Glasses (BMGs)

rehaas2020-05-28T10:26:58-05:00Project Overview: There has been a growing interest in the machining of amorphous metallic alloys, which are also called bulk metallic glasses (BMGs). These materials differ from common polycrystalline metallic alloys, because their atoms do not assemble on a crystalline lattice, and as a result, they have unique physical, mechanical, and chemical properties. Metallic glasses [...]