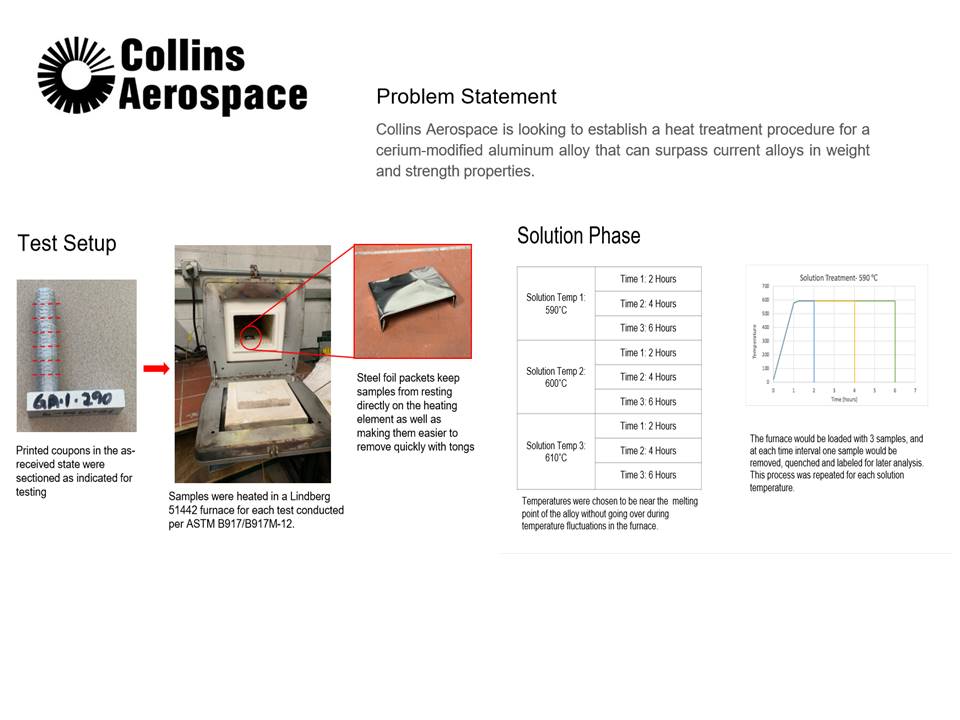

Project Description

Project Overview: The aerospace industry is exploring the use of additive materials (Metal Matrix Composites) in the aircraft manufacturing process. Collins Aerospace has a new nickel-based super Aluminum Alloy that possesses high strength properties and resistance to elevated temperatures. During additive manufacturing (powder metallurgy) one step is Sintering. Sintering is the process of compacting and forming a solid mass of material by heat or pressure without melting it to the point of liquefaction. The objective and goal of this project is to explore the sintering process (heat treatment) to yield the best final materials properties. The team will study the alloy’s heat treating curves and solution treatment cycle to design possible heat treatment options. The team will develop and validate a repeatable and controlled procedure producing a desirable microstructure. The team will utilize a sintering furnace, SEM, optical microscopy, hardness and tensile testers.

Client: Bill Wentland, Collins Aerospace Co.

Student Team: Emma Hazel, Brandon Riehle, Hannah Walker