Project Description

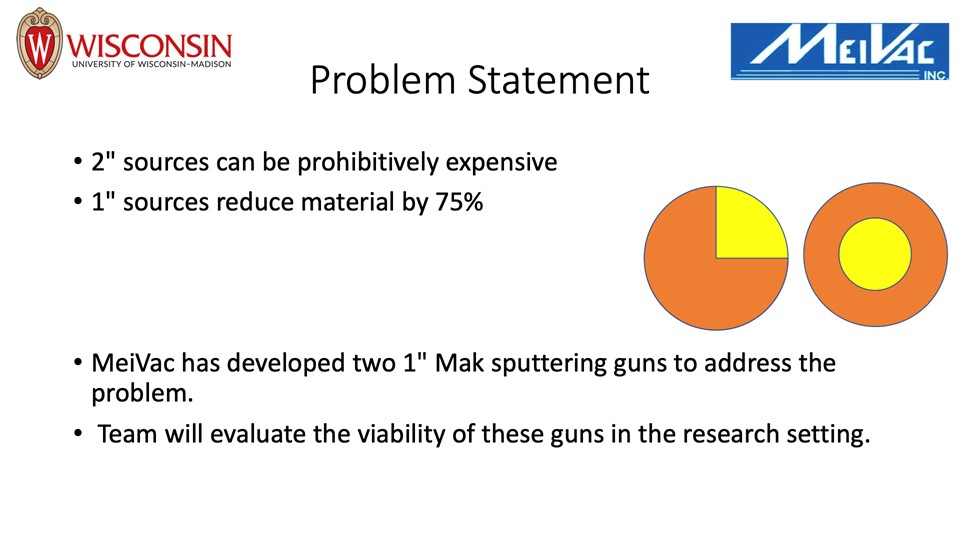

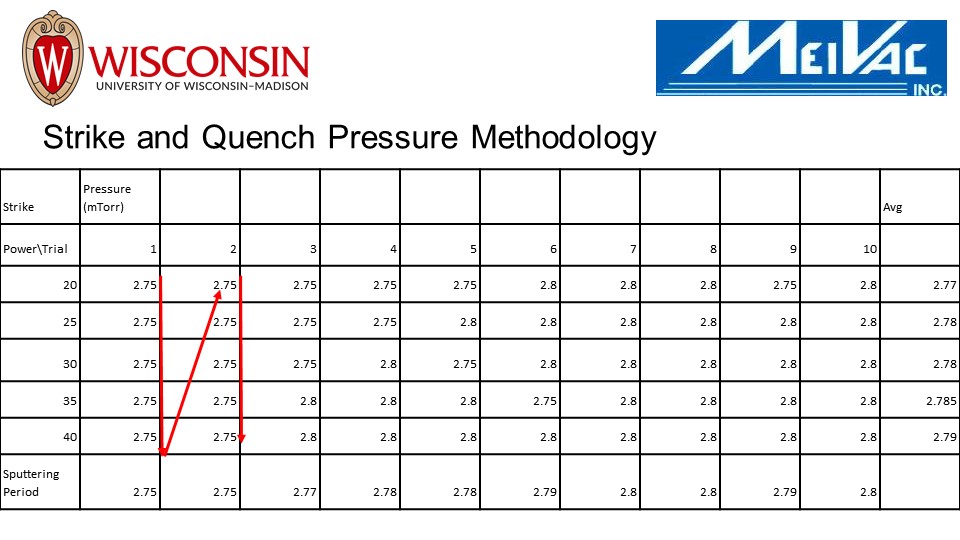

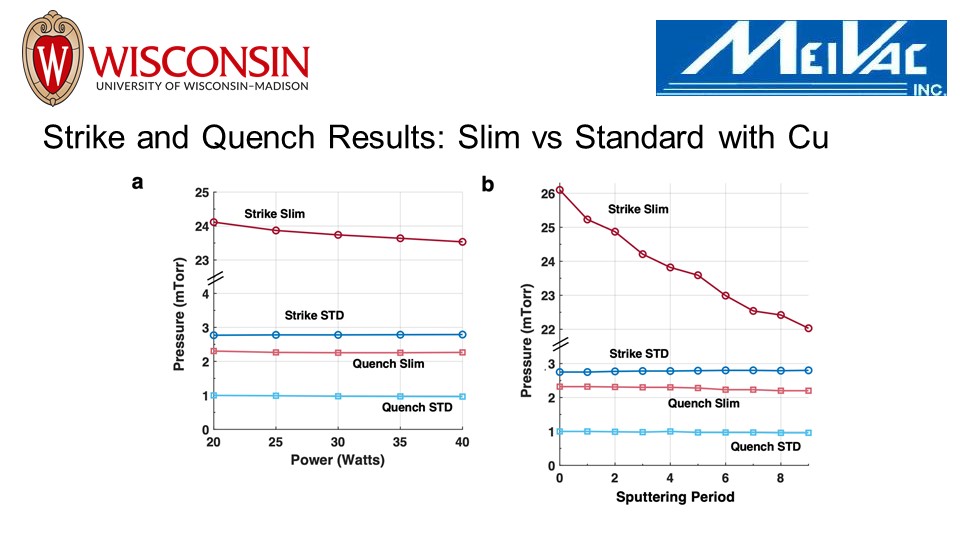

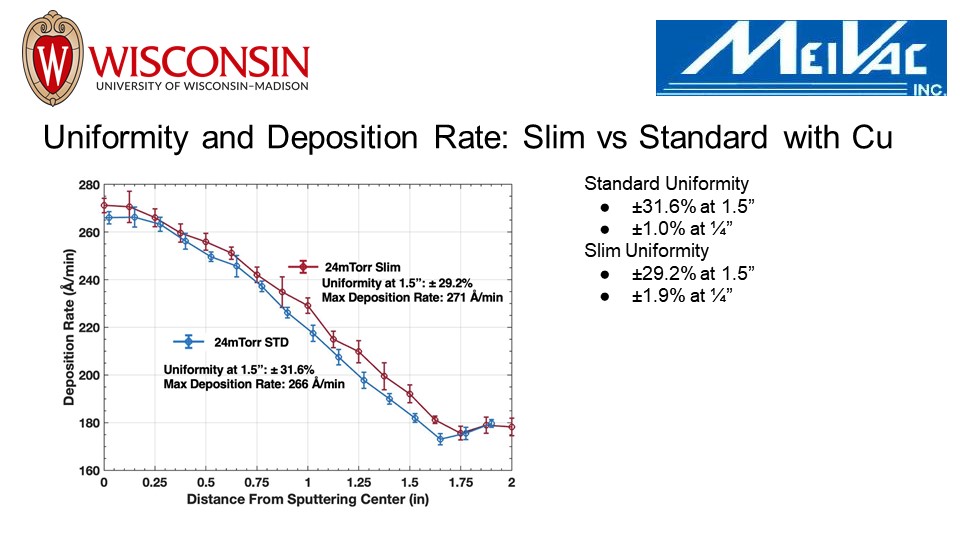

Project Overview: Ferrotec’s MeiVac group is an industry leader in providing high-quality thin film manufacturing systems, components, and process solutions. As a multi-faceted supplier of standard and specialty vacuum processing systems and components used in multiple high technology production and development applications, MeiVac has served markets include data storage, photonics, solar, telecom and Government research and development. Magnetron sputtering is being used to deposit thin films on substrates. Two-inch sample targets are standard for laboratory use, but for precious metal like platinum, even these targets can be prohibitively expensive. New one-inch target designs can allow for a 75% reduction in materials used providing a cheaper alternative. However, it is difficult to generate the required magnetic field with 1” magnet configuration. This project will compare the performance of two 1” Magnetron sputtering source prototype. The team perform a design of experiments to analyze the strike DC voltage /power, Strike pressure threshold, ability to strike at one pressure and then reduce to a lower operating pressure, deposition rates, deposition uniformity over a 50mm fixed substrate, sputtering contamination, and impact of etching patterns on ground shields.

Client: Dr. Chang-Beom Eom, UW Madison, Todd Johnson, Ferrotec MeiVac

Student Team: River Carson, Aiden Ross, Atilla Veyssal, Javier Ramirez Frias