Project Description

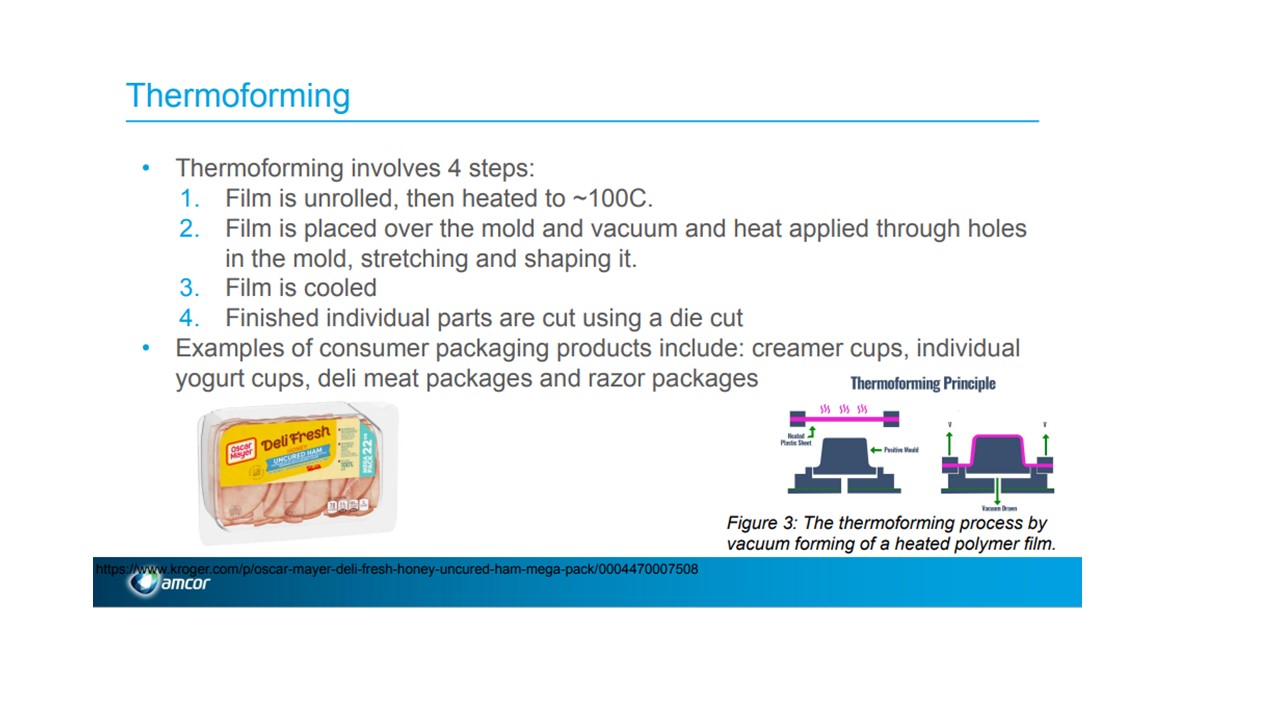

Project Overview: PET (polyethylene terephthalate) is a widely used thermoplastic in the packaging industry. It’s the primary material used to make transparent juice bottles. It is also used for plastic containers and food grade flexible packaging. PET is especially valuable because of its ability to be recycled easily. One of its limitations though, is its heat resistance performance. A material’s heat resistance is its ability to maintain its shape at high temperatures (particularly above its glass transition temp). The typical range of the glass transition temperature of PET is 70-85 ℃. This is relevant because when hot liquids are poured into plastic packages, consumers expect them to maintain their shape. Previous approaches have included mixing in additives or creating PET polymer blends. Other ideas include increasing crystallization rate, or using a different grade of polymer resin which achieves a higher degree of crystallinity after processing. The project team’s goal is to find solutions to improve the existing thermal performance that allows Amcor to maintain the required properties while being sustainable and cost efficient.

Client: Kevin Nelson, Greg Carpenter, Jacob Lasee, Amcor Flexibles North America

Student Team: Nicole Fessler, Bennett Baumann, Lazar Vucicevic, Tyler Daffner