Project Description

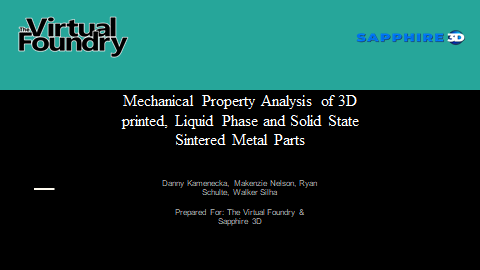

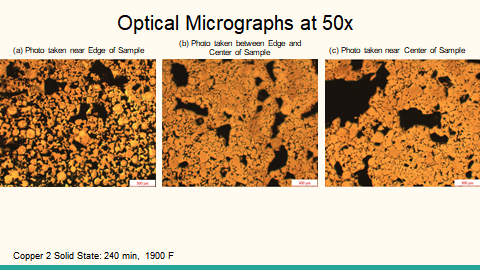

Project Overview: Powdered metallurgy in Fused Deposition Modelling (FDM) and 3D printing is new technology in the materials science and engineering manufacturing world. The Virtual Foundry is manufacturing small metal parts using a 3D printer with a powder metal filament, and the parts are then sintered (compacted and formed a solid mass of material at high temperatures) in a furnace. The finished products are still porous. The objective and goal of this project will conduct a set of design of experiments with 316L stainless steel samples identifying mechanical properties under various furnace conditions (sintering temperature and soak time). Samples will be printed and sintering; coupons will be placed in epoxy molds, grinded and polished and then analyzed. The team will utilize a vacuum, Argon furnace (UW or TVF access), optical microscopy (SEM), and tensile and hardness testers.

Clients: Dr. Tricia Suess, Dr. Brad Wood, The Virtual Foundry

Student Team: Danny Kamenecka, Makenzie Nelson, Ryan Schulte, Walker Silha