Project Description

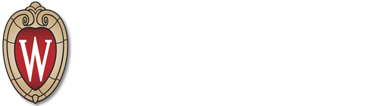

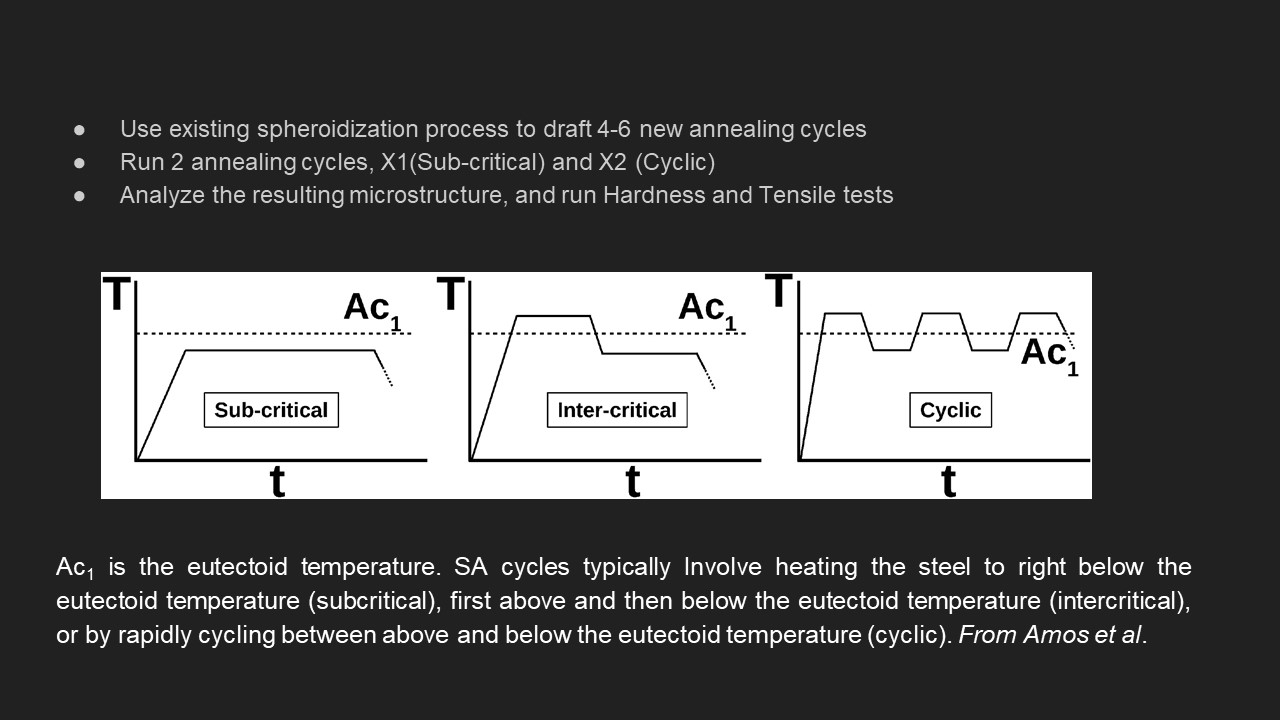

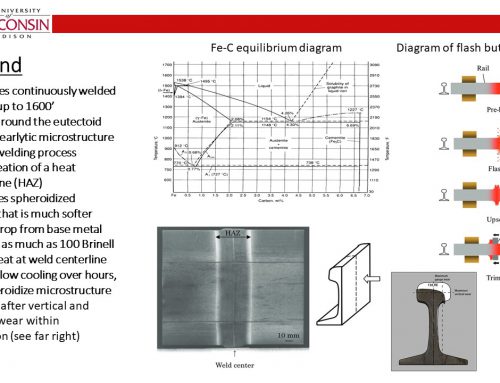

Project Overview: Charter Steel spheroidize anneals (SA) coils of steel every day in its processing facilities to produce a soft microstructure that our customers can more easily cold form into various applications. At Charter, SA occurs in either box furnaces (batch operation) or continuous furnaces. In either case the material is heated up to a sub-critical or inter-critical temperature then furnace cooled to produce a microstructure of spheroidized carbide for optimal formability. Charter measure the success of the SA cycles by rating the microstructure of the material and evaluating the mechanical properties (tensile test, hardness) after SA. Charter produces over 200 different steel grades and it uses about 10 different SA cycles on those grades. There are some steel grades do not get spheroidized as well as desired with the current cycles. The goal of this project is to assist Charter Steel in optimizing the annealing cycles on those problem steel grades.

Client(s): Eric Wagner, Matthew Bollman, Mike Dahl, Charter Steel

Advisor(s): David Trautner, Tim Matchulat, Charter Steel

Team: Tim Hinkens, thinkens@wisc.edu (Leader, Communicator)

Jacob Perez, jgperez2@wisc.edu (Technical Engineer)

Alex Horvath, ajhorvath@wisc.edu (Accountant/Project Management)