Project Description

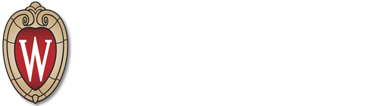

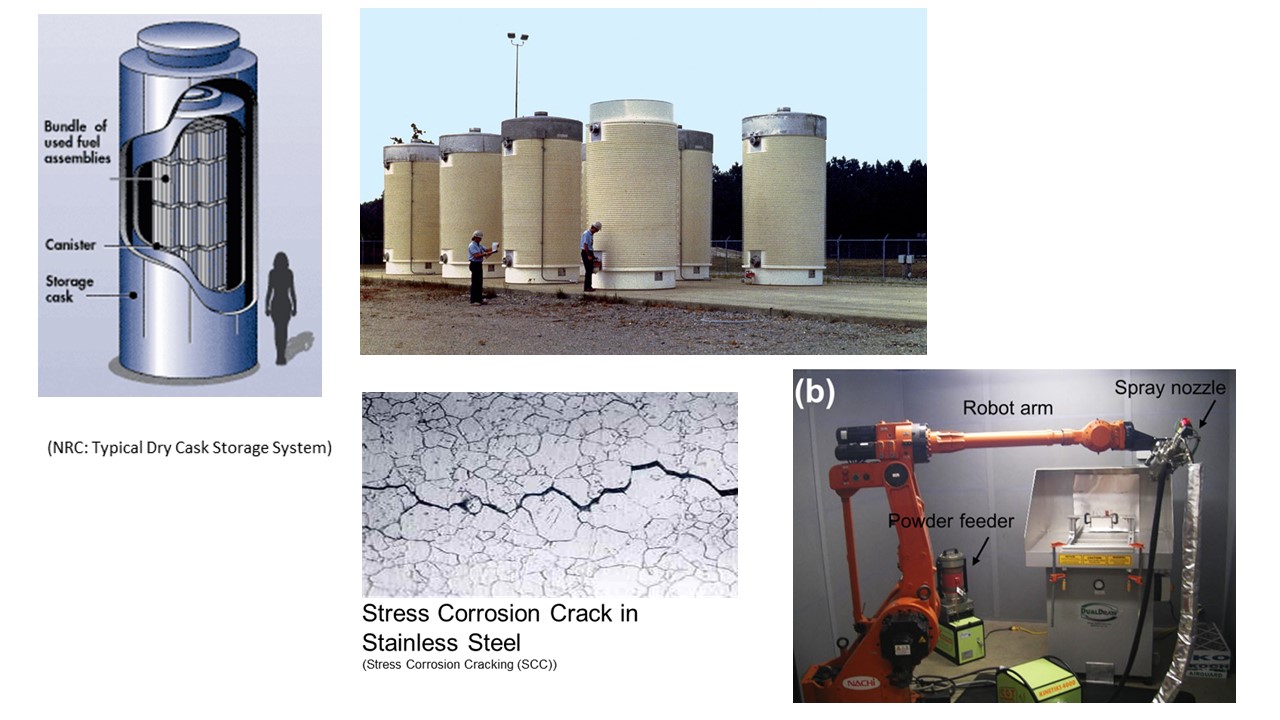

Project Overview: Spent nuclear fuel (SNF) storage in dry casks experience stress corrosion cracking (SCC) when stored for long periods of time in corrosive environments. Repair of SCC is needed in order to maintain the structural integrity and safety of the dry casks. Cold spray has been identified as a promising, scalable solution to the repair and maintenance of SNF dry cask storage. This project investigates the effectiveness of cold spray as a repair method for SCC through mimicking cracks using electrical discharge machining (EDM) to create cracks in 304L stainless steel. Characterization and analysis will include the use of a variety of test equipment including SEM, XRD, tensile testing, optical microscopy and micro indention.

Client: Kumar Sridharan, Research Professor, Department of Engineering Physics, University of Wisconsin-Madison

Advisor: Sung Yeom, Graduate student, University of Wisconsin-Madison

Team: Maureen Duthie, duthie@wisc.edu (Leader)

Nick Pocquette, pocquette@wisc.edu (Project Management)

Evan Rocco, rocco2@wisc.edu (Technical Engineer)

Abby Pratt, atpratt@wisc.edu (Accountant, Budget, Communicator)