Project Description

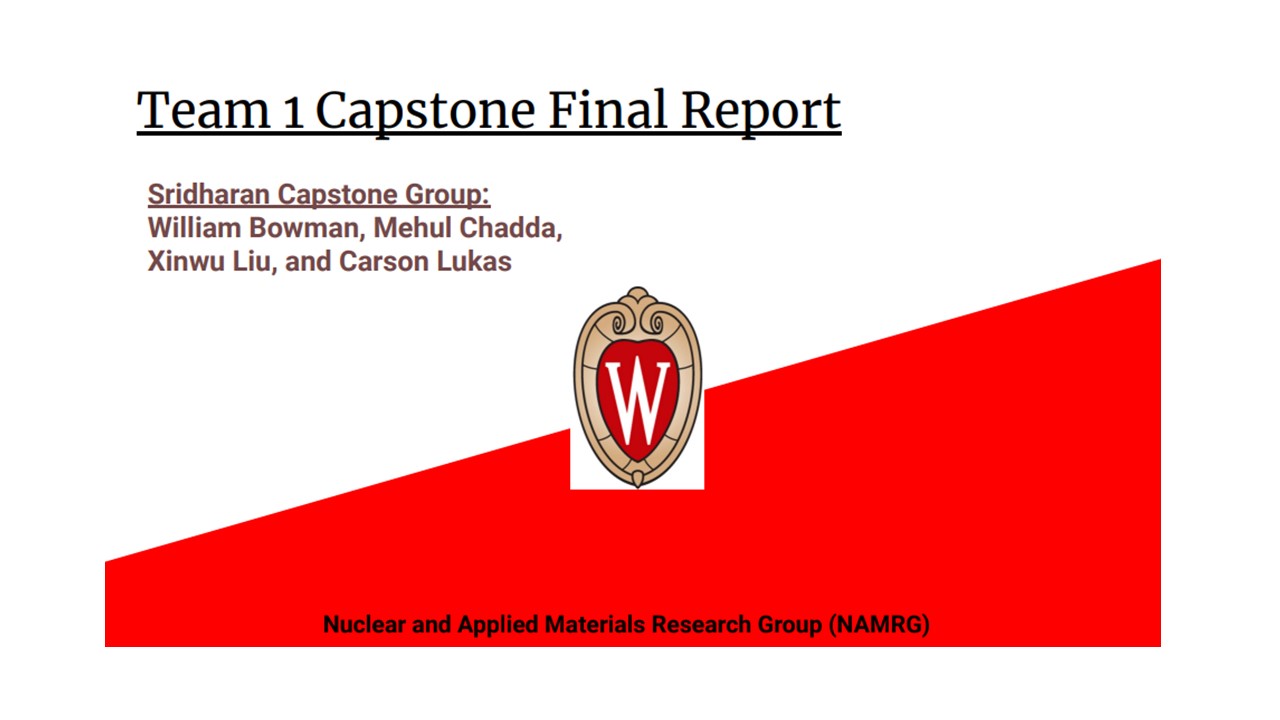

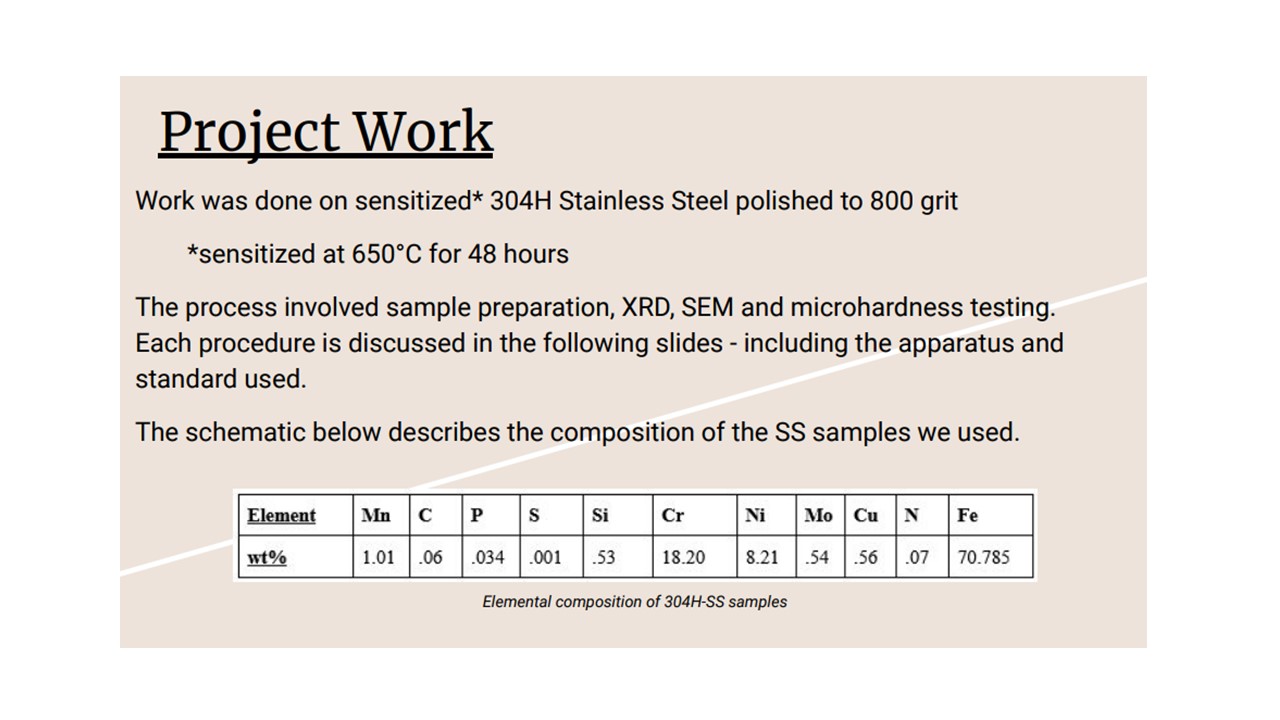

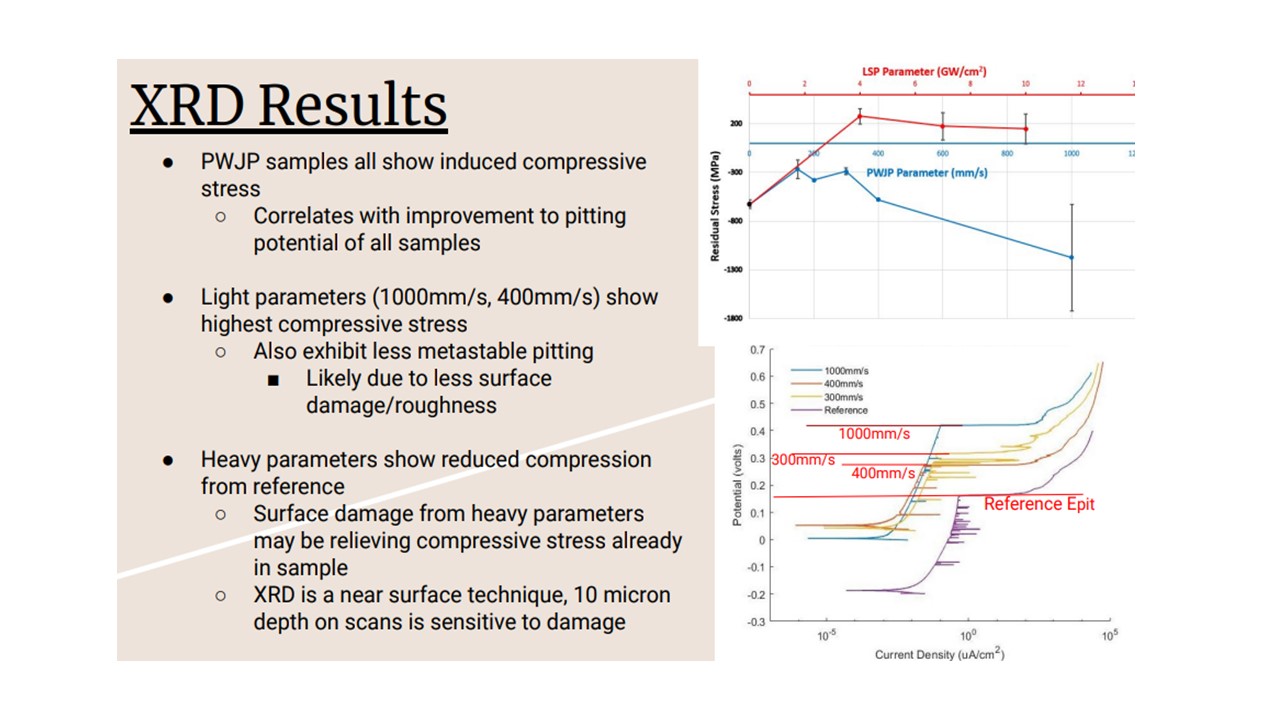

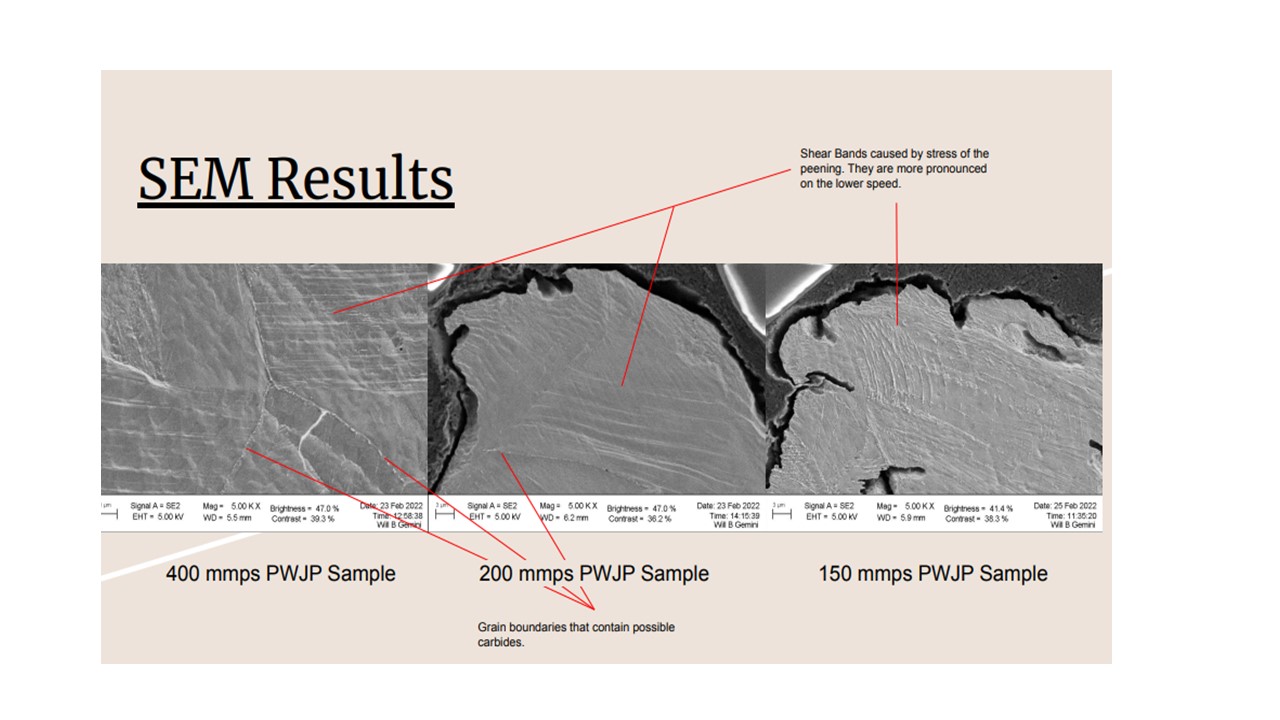

Project Overview: Long term storage of spent nuclear waste is an integral part in the lifecycle of materials related to nuclear power production; the containment of this radioactive material for time periods on the scale of decades is paramount to the safety of the public and environment. Dry Cask storage is the contemporary solution to this problem, which involves storing the waste in a stainless-steel cask. Over time the welded regions of theses casks corrode, can undergo corrosion from the corrosive species in the environment leading to the possibility of stress corrosion cracking which can compromise the integrity of the container and release its hazardous contents to the environment. An innovative new approach to mitigate stress corrosion cracking (SCC) is the use of surface peening to induce compressive residual stress to heal sites of SCC and mitigate future SCC proliferation. A variety of peening technologies including laser peening, water jet peening, and ultra-nanocrystalline surface modification are being investigated. This project will focus on residual stress measurements of samples peened by different technologies and supported by microstructure and property evaluations with techniques including SEM, XRD, EDS, and microhardness evaluations.

Client: Dr. Kumar Sridharan, UW-Madison

Student Team: Will Bowman, Carson Lukas, Xinwu Liu, Mehul Chadda