Project Description

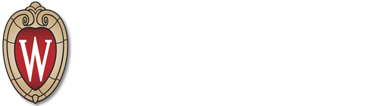

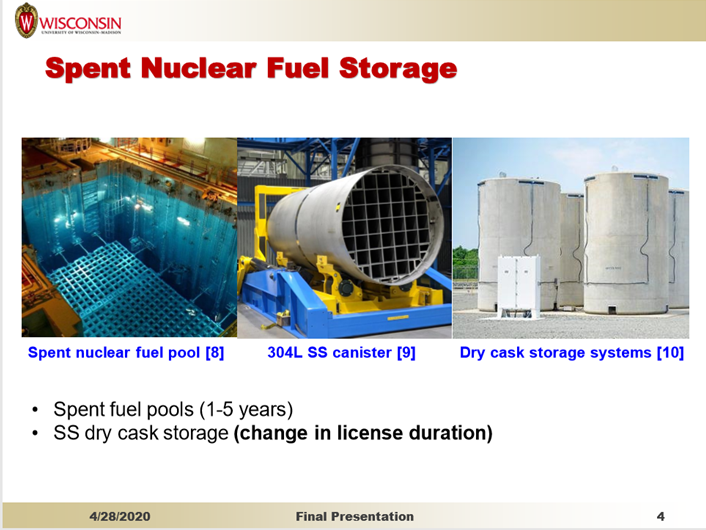

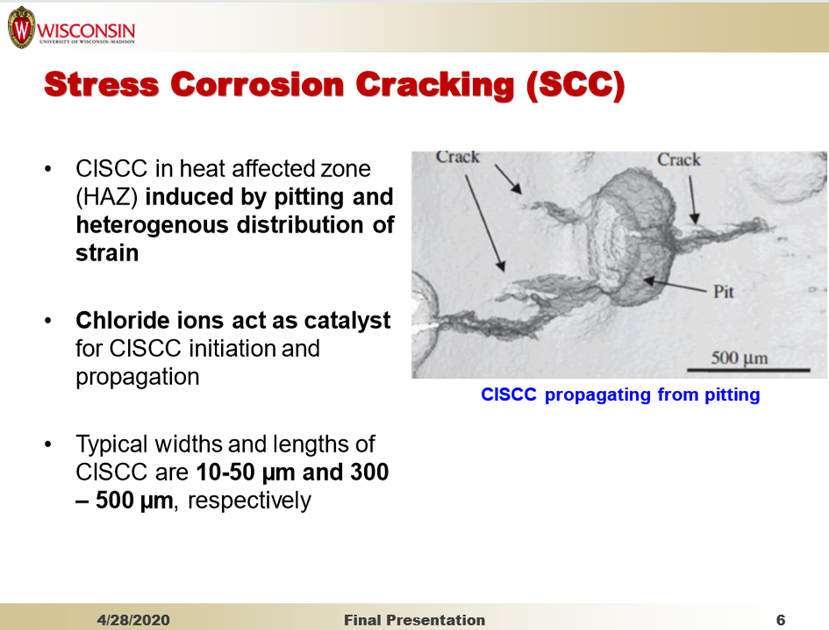

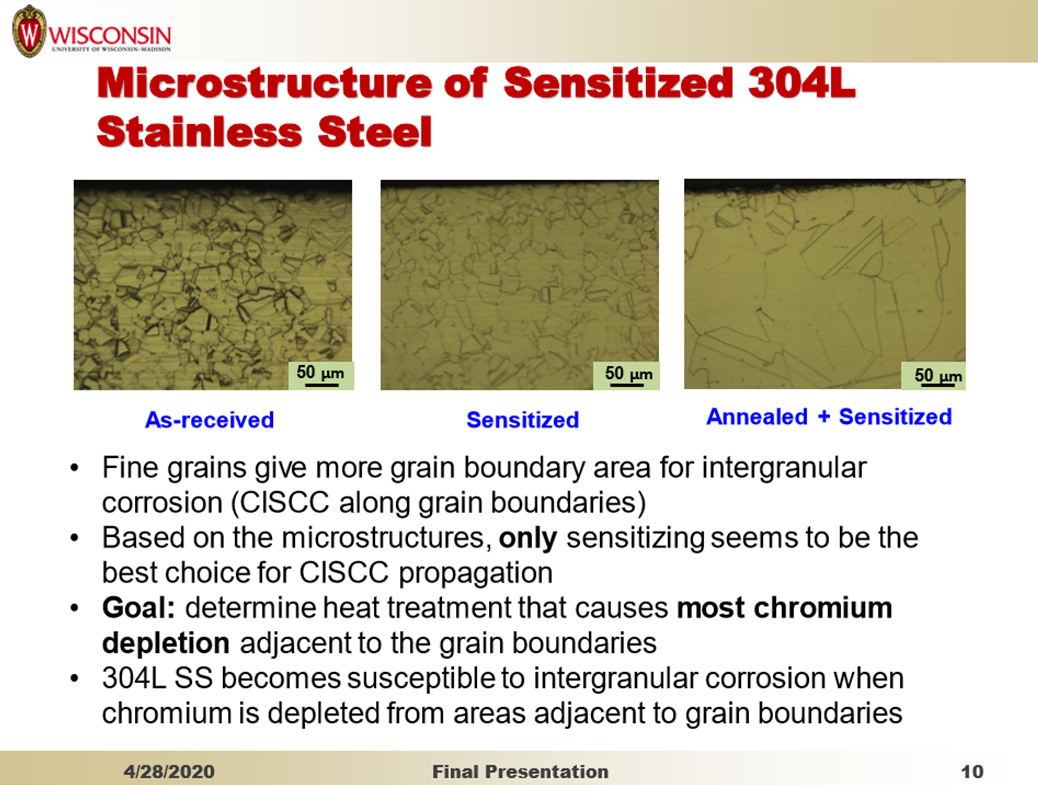

Project Overview: 304 Stainless Steel nuclear fuel storage canisters experience general corrosion and stress corrosion cracking when stored for long periods of time in warm weather environments. These cracks need to be reduced or eliminated in order to maintain the structural integrity of the spent fuel storage devices. These devices are large canisters of 304 grade stainless steel (SS) encased in water and concrete. A scalable process can be designed using cold spray coating techniques. This project will be using existing University of Wisconsin-Madison laboratory facilities and cold-spray techniques to coat 304 SS in an effort to maintain tensile strength and eliminate cracking. The objective and goal of this project is to characterize and analyze samples use of a variety of test equipment – SEM XRD, hardness testers, optical microscopes and micro indenters.

Client: Dr. Kumar Sridharan, University of Wisconsin – Madison, Department of Materials Science and Engineering

Student Team: Rogelio Ramirez, Lucas Morrissey, John Lacy