Project Description

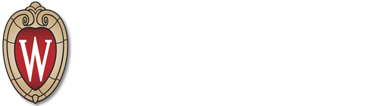

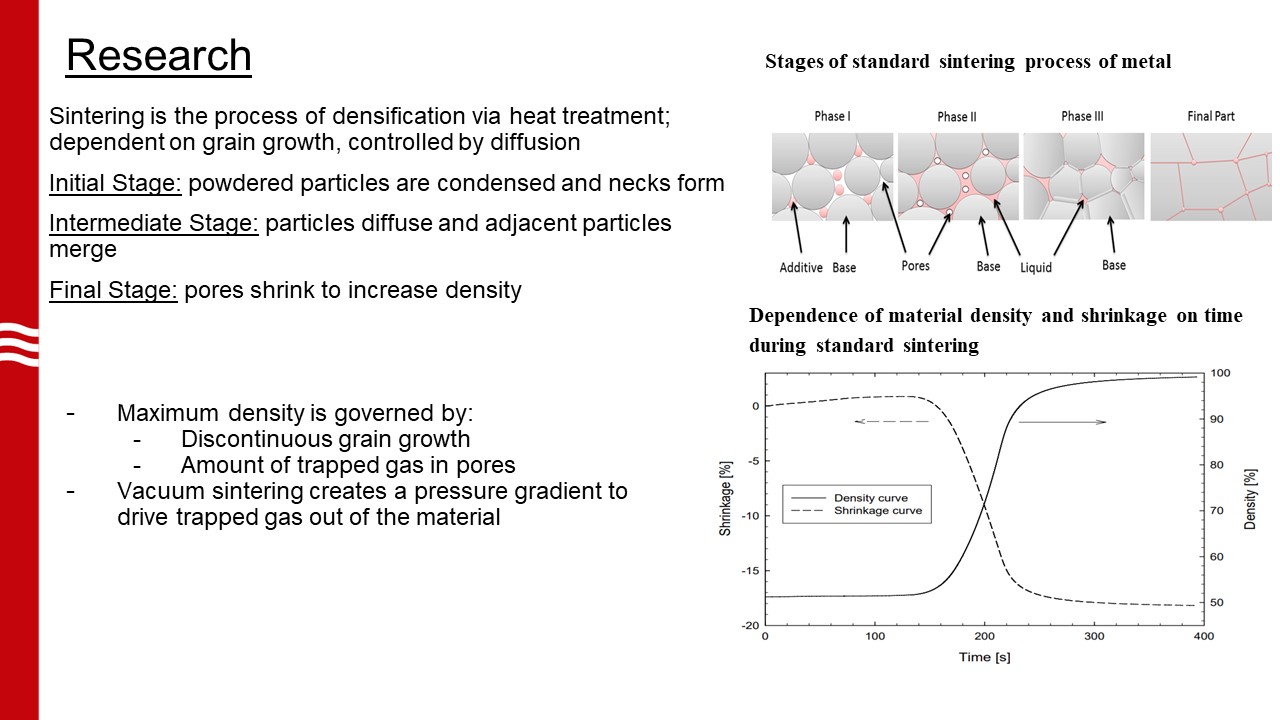

Project Overview: Small metal parts are being manufactured using a 3D printer with a powder metal filament, and then the parts are sintered (compacted and formed a solid mass of material) in a furnace. The current sintering process used by The Virtual Foundry has some issues with incomplete sintering and oxidation of small metal parts. This project will conduct a set of design of experiments with sinter parts manufactured with different powder metal filaments under various furnace conditions (temperature/time).

Client: Dr. Tricia Suess, President, The Virtual Foundry

Advisor: Dr. Brad Wood, Engineer, The Virtual Foundry

Team: Evan Blanchard, eblanchard2@wisc.edu (Leader)

Rhea Christopherson, rlchristophe@wisc.edu (Technical Engineer)

Trevor Macey, tmacey@wisc.edu (Accountant)

Edward Jornlin, jornlin@wisc.edu (Communicator)