Project Description

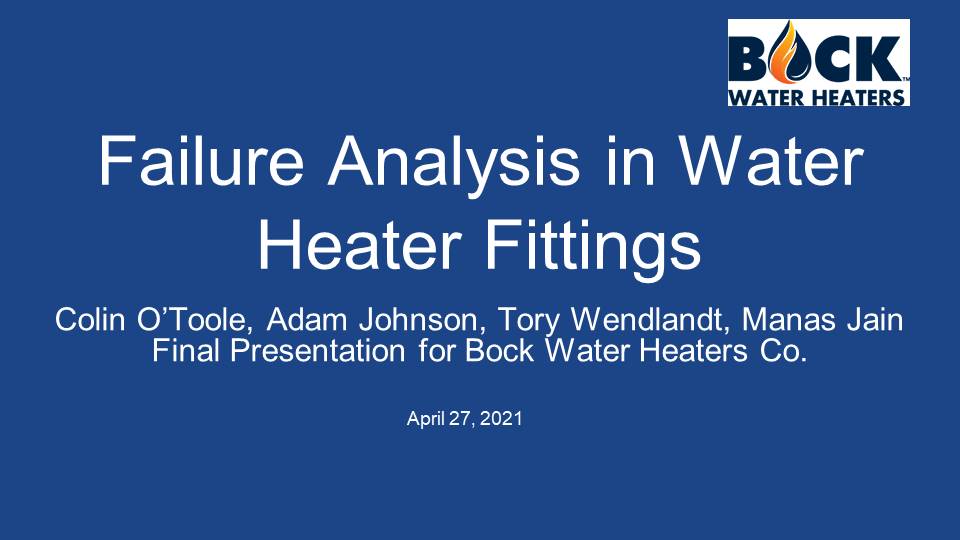

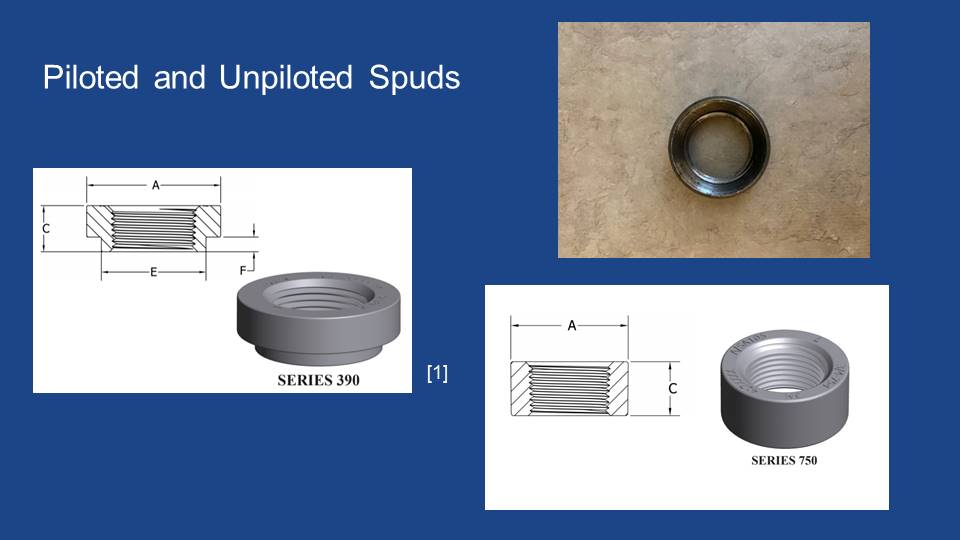

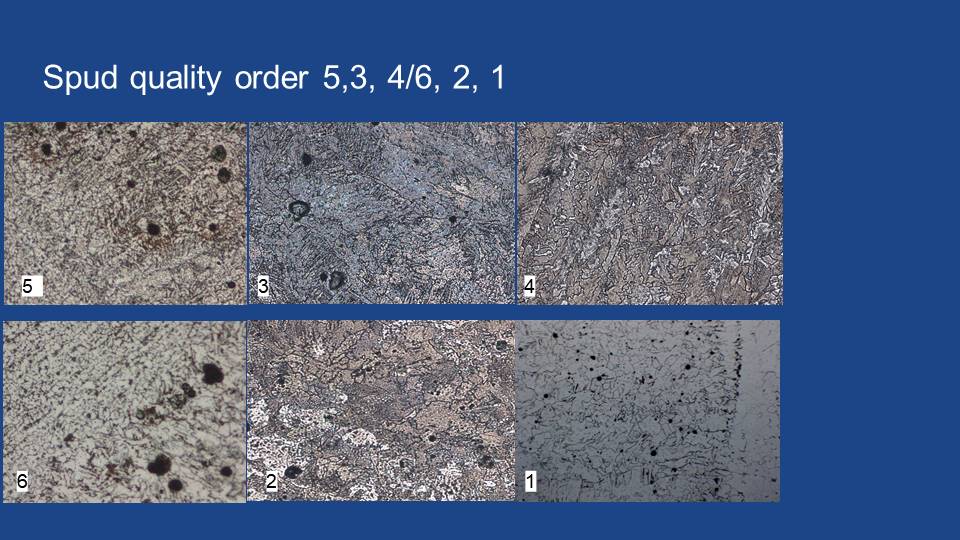

Project Overview: Commercial hot water heaters are required to function according to industry standards (consistent, efficient, and leak-free) in order to provide a building with the hot water supply it needs. Bock Water Heaters (BWH) designs commercial hot water heaters which generally includes applying a thick liquid porcelain enamel to one side of a low carbon steel fitting component. Fittings (valves and flanges) welded to the tank are a common failure (leak) issue. These failures are most commonly found before the heaters leave the BWH production facility, leading customers to believe this is an internal production flaw. The project team will examine BWH production processes and attempt to determine a root cause of the failures. The team will analyze welds, their placement relative to the casing of the tank and fittings, and failure rates in different types of welded fittings. The team will utilize a SEM optical microscopy, hardness and tensile testers to evaluate and analyze carbon content, grain structure, material properties, and strength.

Client: Quinn Blankenheim, Bock Water Heater, Madison, Wisconsin

Student Team: Manas Jain, Colin O’Toole, Adam Johnson, and Tory Wendlandt