Project Description

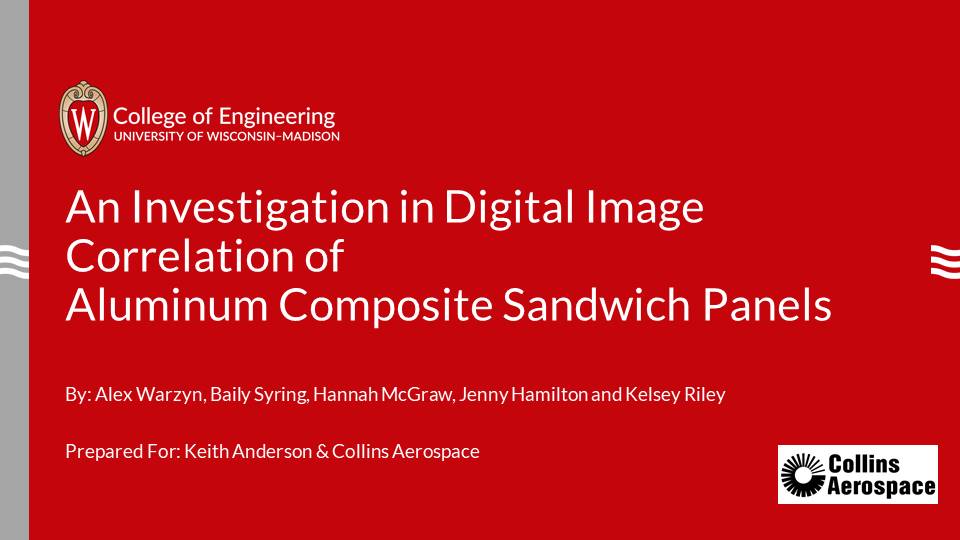

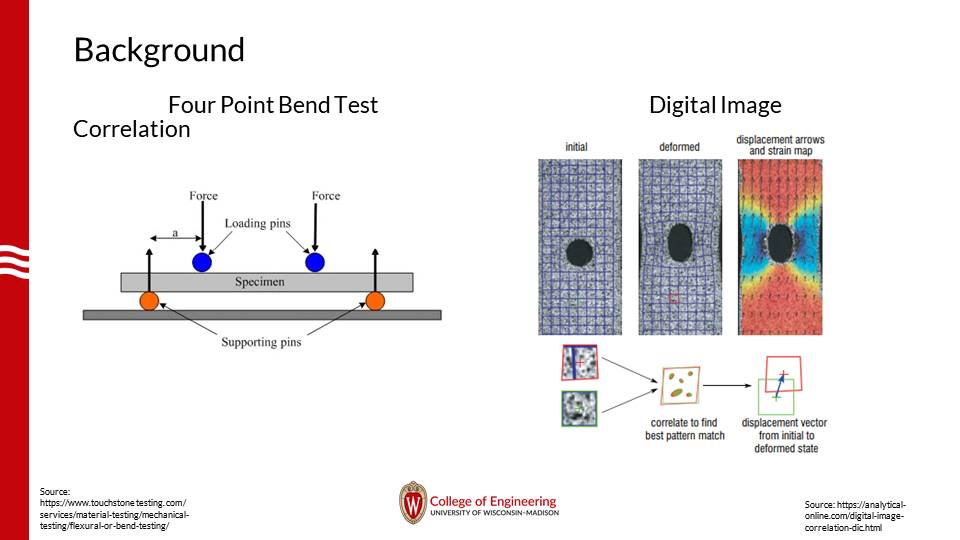

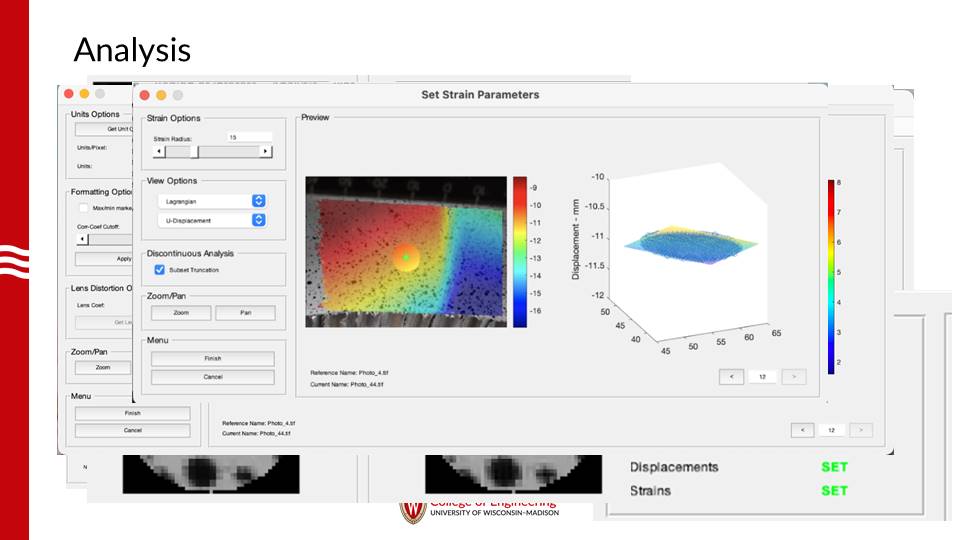

Project Overview: Collins is an aerospace company that designs, builds, and manufactures the interiors of aircraft for different airlines. Most of these interiors are designed in light metal or composite materials due to their high strength, toughness, and low density. Before developing these materials into products, material properties must be analyzed and integrated with design standards. Collins provided us with FSI-PS-4004 Ty 7 Cl 1 Aluminum honeycomb panel. The team will procure or build a 4-point bending fixture for mechanical testing purposes. The objective for this project is to create an alternative method to replicate imaging analysis methods available on the market and use this tool to produce a Full Field Stress-Strain map of a honeycomb aluminum sample (dog bone). The team will prepare the honeycomb panels, design of the experimental 4-point bending fixture, perform the 4-point bending tensile tests using engineering standards, and conduct SEM imaging analysis using UW-Madison laboratory facilities.

Client: Keith Anderson, Collins Aerospace, Federal Way, Washington

Student Team: Bailey Syring, Hannah McGraw, Alex Warzyn, Kelsey Riley, and Jennifer Hamilton