Project Description

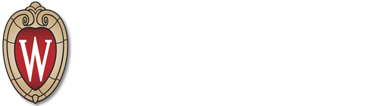

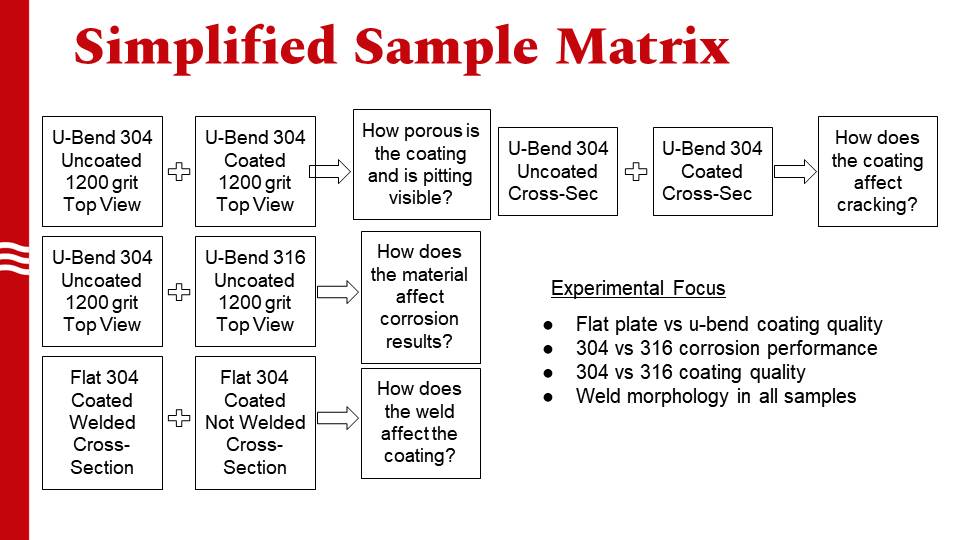

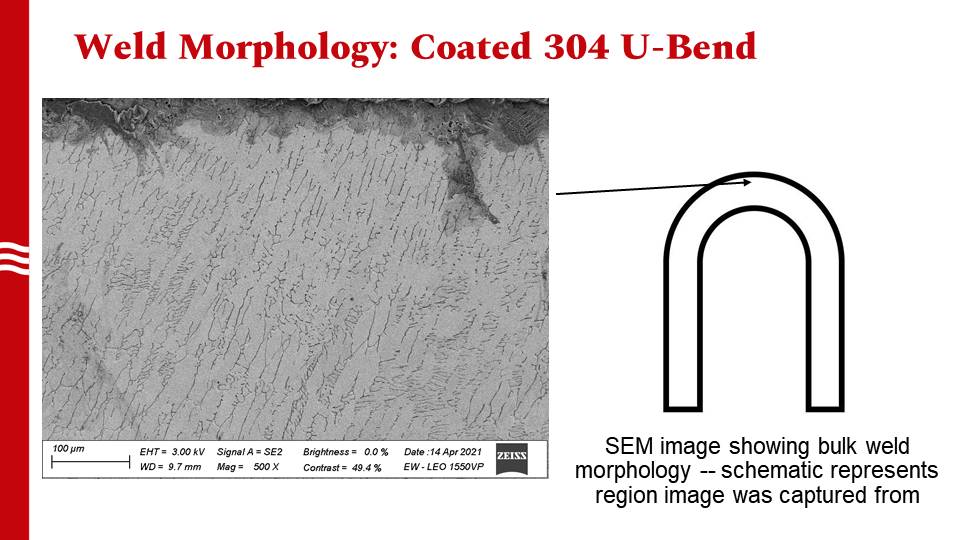

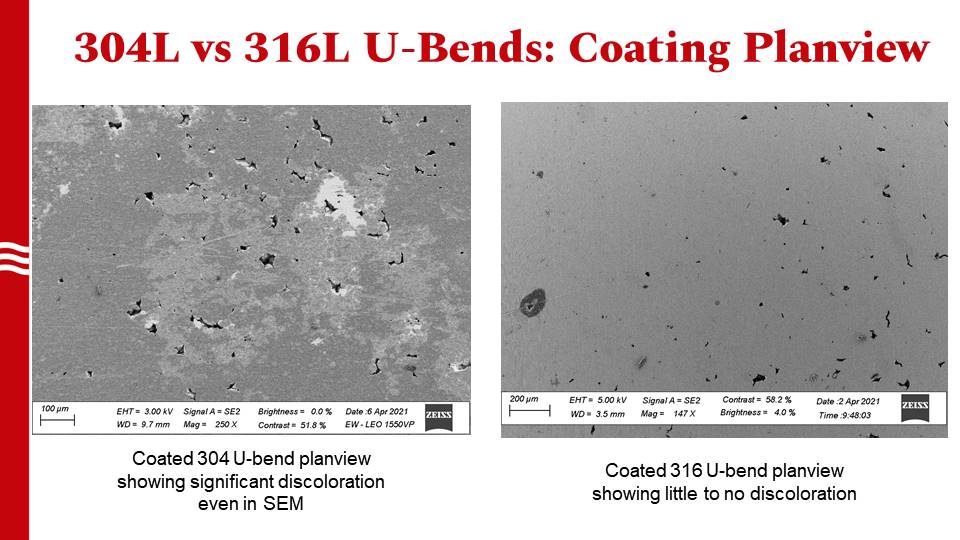

Project Overview: Steel dry cask fuel storage canisters are the primary method of storing nuclear fuel in the country. These canisters tend to crack due to corrosion and tensile stress over time, which impacts their durability. Previous capstone groups have shown that a cold spray process can be used to deposit a coating that fixes simulated cracks on samples of stainless steel canisters. The canisters are under tensile strength at the surface and have heat-affected zones that are particularly susceptible to corrosion. This project will show the cold spray process is viable for welded samples under simulated stress and in heat-affected zones. Cracks from corrosion and tensile stress will be simulated and cold spray methods will be used to deposit steel onto the cracks. The samples will be analyzed with SEM imaging, hardness tests, and AFM analysis. We will follow MIL-SPEC engineering standards, as this project has potential military applications.

Client: Dr. Kumar Sridharan, Department of Materials Science and Engineering University of Wisconsin-Madison

Student Team: Lane Meddaugh, Evan Willing, Alixandra Rosenblat, and Vishnu Ramasawmy