Project Description

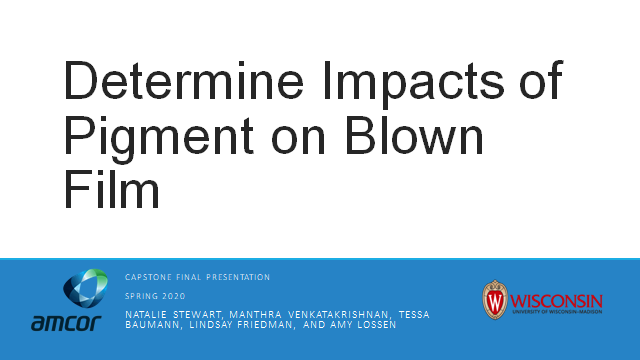

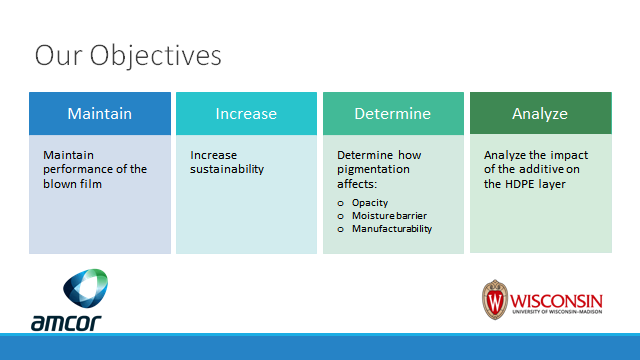

Project Overview: Amcor Flexibles North America has pledged to develop more sustainable packaging that is recyclable or reusable by 2025. The blown film process, used to produce polyolefin-based film, is the most widely used conversion technique for film applications. Originally, mono-layer dies were used, but it is now very common for blown film to be produced from multi-layer dies, depending upon the final requirements of the film. Amcor’s goal is to maintain the performance of their blown film barrier while still upholding the sustainability. This project will explore at different grades of high density polyethylene to understand what occurs at the molecular level and how that would affect larger properties. The team will analyze the effects of pigmentation on 1) both opacity and moisture barrier and 2) observe the crystallinity and manufacturability of the different grades of HDPE in regards to formability. We will conduct a design of experiments on multiple grades of HDPE on a blown film machine by varying the amount of resin and pigment. The project team’s goal is find the optimal combination that allows us to maintain the required properties while allowing a sustainable and cost efficient alternative to the current structure.

Clients: Megan Goodrich and Kevin Nelson, Amcor Flexibles North America

Student Team: Teresa Baumann, Manthra Venkatakrishnan, Amy Lossen, Natalie Stewart, Lindsey Friedman